Cummins Inc. is partnering with Achates Power Inc. to develop and demonstrate a technologically advanced engine for the next generation of U.S. combat vehicles.

Cummins received a $47.4 million contract awarded by the National Advanced Mobility Consortium for the Advanced Combat Engine (ACE) project, led by Cummins Corporate Research and Technology and supported by Achates Power.

ACE is a key component of the Army's 30-year strategy to modernize tactical and combat vehicles, with potential for future production configurations being used in the Bradley family of vehicles and the Next Generation Combat Vehicle.

Wayne Eckerle, vice president of corporate research and technology for Cummins, says, “We are confident we can achieve significant improvements in mobility, power, range, and fuel economy, creating combat vehicles that are safer [and] faster and have clear advantages in the field."

The goal of the project is to significantly improve the performance, survivability, and range of ground combat vehicles while reducing fleet fuel use. Cummins and Achates plan to reach these goals by reducing heat rejection by 21 percent compared to current Cummins-supplied combat vehicle engines, as well as improving power density by more than 50 percent, and reducing fuel use by 13 percent.

“This award builds upon 14 years of extensive development by Achates Power to modernize and optimize the opposed-piston engine,” notes David Johnson, Achates Power's chief executive officer.

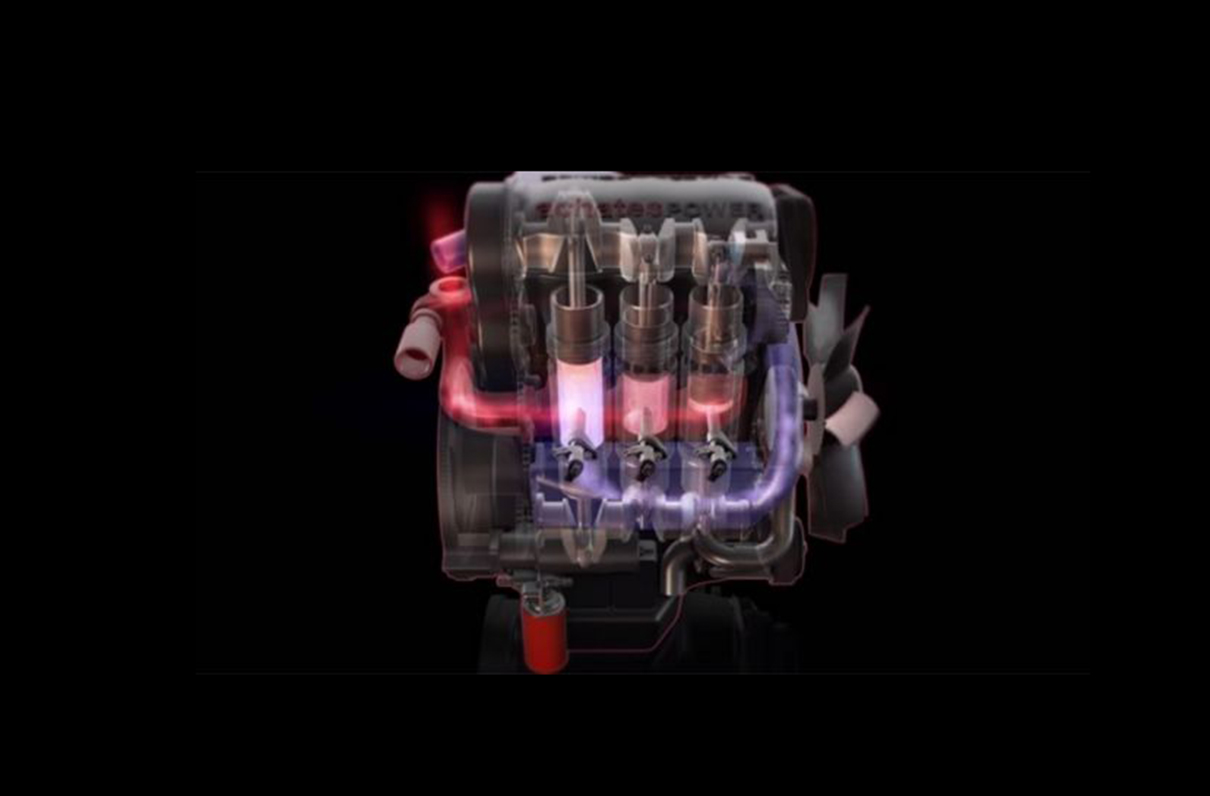

The challenges faced in developing ACE, Cummins points out, were quickly coming up to speed on the fundamentals of the opposed piston, 2-stroke (OP2S) architecture, both from a combustion and mechanical systems standpoint.

In overcoming those challenges, Cummins used its partnership with Achates Power and their prior joint development activity to adapt analysis-led design processes to the unique architectural elements of the ACE.

The current prototype engine being prepared for demonstration has a maximum power of 1,000 horsepower with 4 cylinders (8 pistons) and a total displacement of 14.3 liters (70-horsepower/liter). The prototype uses two fuel injectors per cylinder and is aspirated by a combined mechanical supercharger/turbocharger based air handling system. It will deliver a total cooling system heat rejection load of 0.45 kW/kW (thermal/power output ratio) or lower.

The OP2S engine has a fundamental reduced heat rejection advantage due to lower combustion chamber surface-to-volume ratio, Cummins says. The two-stroke cycle, with proprietary designs for cylinder and piston cooling to manage thermal loads, provides an advantage in power density.

ACE is being developed for full-desert-condition capability and operating on all specified military fuels, although the initial demonstration will be on JP8, according to Cummins.

Next year, an overarching project integrating and validating ACE as part of a system of other key innovative power train technologies will be conducted by the U.S. Army Tank Automotive Research, Development, and Engineering Center's Ground Vehicle Power and Mobility technology focus group.

Along with ACE, the system will incorporate an integrated starter/generator, advanced combat transmission, advanced thermal management system, and other key components of the advanced powertrain demonstrator. Results of this program will position the Army and the defense industrial base for future generations of combat vehicles.

About the author:Alan M. Petrillo is a Tucson, Ariz., journalist who writes for national and regional magazines and newspapers. He's the author of several books on historical military firearms; two historical mysteries, Full Moon and Asylum Lane; and his latest historical thriller, A Case of Dom Perignon; all available at www.amazon.com.